Lockpicking

Created: 2020-03-10 15:16:55 -0700 Modified: 2020-03-10 16:51:01 -0700

- MIT apparently wrote a guide to lock picking that I found through the locksport Wikipedia page.

- I think the first 6 chapters were pretty good without even having locks to pick yet. Chapter 7 seemed worthless. Chapters 8 and 9 seem like they might be nice once I actually have locks.

- Some good picture resources:

- An animation of a key lining up key pins and rotating the plug: https://media.giphy.com/media/YXfWKWbTjOUj6/giphy.gif

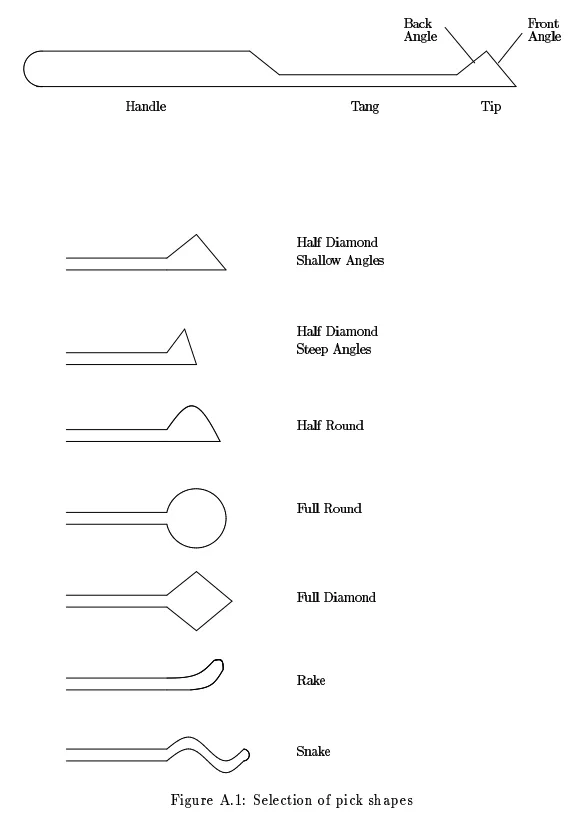

- Pick shapes from the MIT guide:

Basics of picking one pin at a time

Section titled Basics of picking one pin at a timeCopied from the MIT lockpicking guide:

Thus, the procedure for one pin at a time picking a lock is to apply a sheer force, find the pin which is binding the most, and push it up. When the top of the key pin reaches the sheer line, the moving portion of the lock will give slightly, and driver pin will be trapped above the sheer line. This is called setting a pin.

This flaw is apparently the most common flaw of locks, and cheapo locks don’t have the fine tolerances to prevent this from working. However, better-constructed locks will prevent you from picking one pin at a time.

Snap guns or lock-picking guns

Section titled Snap guns or lock-picking gunsThe way to open a lock is to get the gaps between the driver pins and the key pins to line up with the sheer line, then you can rotate the plug. A snap gun kind of slams/vibrates a pick against all key pins at once in the hopes that the gaps line up quickly (see this reference picture).

- Many of these terms come from this glossary or MIT’s lockpicking guide

- Keyway: the part of the plug where you insert the key

- Plug: a cylinder which can rotate when the proper key is inserted

- Ward: protrusions on the side of the keyway that prevent the wrong key from being inserted. The key itself will have ridges/valleys to match these wards.

- Hull: the non-rotating part of the lock (unlike the plug, which does rotate)

- Pin 1: the first pin touched by the key. Higher pin numbers are farther into the lock.

- Key pin: any pin that touches the key.

- Driver pin or top pin or sometimes just driver: any pin that sits adjacent to a spring. They’re not attached to the key pins; the gap between them is necessary for the plug to be able to rotate. When all of the gaps line up across the sheer line, then plug can rotate. The key pins don’t fall out because they’re stopped against the warding in the lock.

- Sliding allowance / tolerance: this refers to the gap size on some locks being big enough to allow multiple keys to open the lock. The goal of any good lock is to minimize the tolerance.

- Flatland model: this simplifies a lock to just two sliding plates to demonstrate most terms/techniques.

- Binding a pin: applying sheer force to the lock so that pins get stuck against the side. Once a pin is bound, it can be set with a pick, which will then align the gap between driver pin and key pin with the sheer line and bind another pin.

- Setting a pin (related to a set): this is when the driver pin goes above the sheer line

- Tensioner: AKA a tension wrench, e.g. any of these. It’s just a tool to put torque on the lock while you’re picking it.

- Scrubbing (reference): when you move a lockpick all the way to the back of the hull and then drag it back out over the pins while applying torque so that the driver pins get stuck above the sheer line.

- Raking: basically scrubbing but in both directions (i.e. you contact the pins on the way in and out of the lock)

- Both raking and scrubbing can set most of the pins for you, but you may have to go back and manually finish the rest.